Contact : +919980224378

Thermal Spray Buffalo Manufacture is a crucial industry in the realm of advanced manufacturing and material science. This process involves applying protective coatings on various surfaces to enhance durability, reduce wear, and improve performance. In this detailed overview, we will explore the significance of thermal spray technology, the benefits it offers, and the role of buffalo manufacturing in this domain.

What is Thermal Spray Technology?

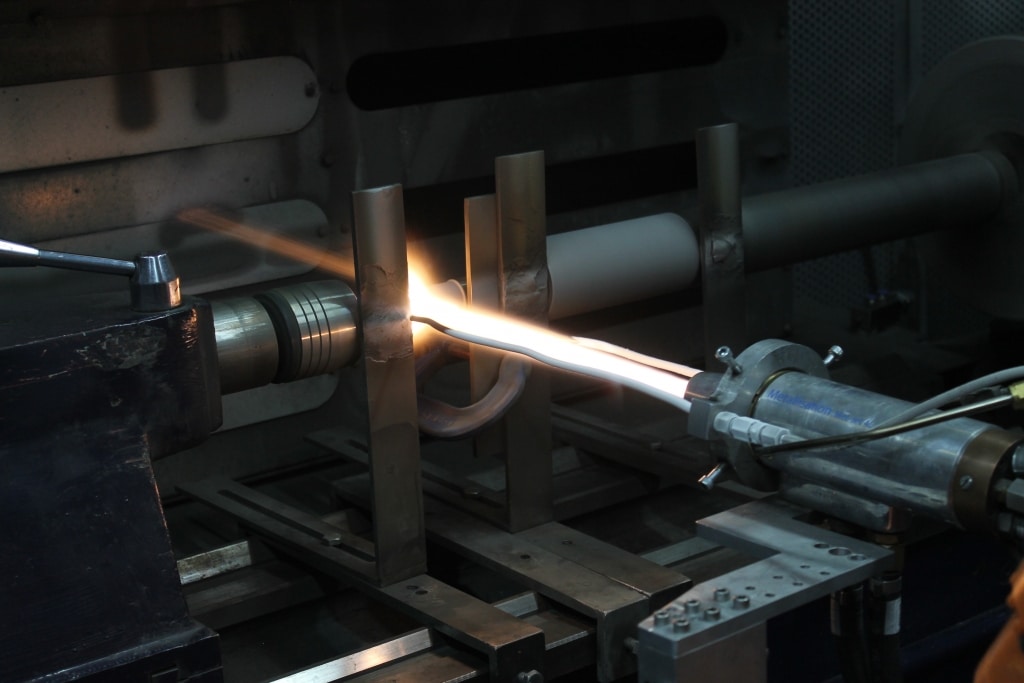

Thermal spray technology is a process used to apply a coating of molten or semi-molten material onto a substrate. This method is widely used to improve the surface properties of components and structures. The coatings created through thermal spraying can offer enhanced resistance to corrosion, erosion, and high temperatures, making them invaluable in various industrial applications.

Buffalo Manufacture in Thermal Spray

Buffalo manufacture refers to the production and application of thermal spray coatings using buffalo-based processes. This innovative technique integrates buffalo-derived materials, which are known for their unique properties, into the thermal spray process. Buffalo materials are often used due to their high strength and durability, which make them ideal for protective coatings.

Key Benefits of Thermal Spray Buffalo Coatings

-

Enhanced Durability: Thermal spray buffalo coatings provide exceptional durability and resistance to wear and tear. These coatings can significantly extend the lifespan of components and reduce maintenance costs, making them an ideal choice for industries that require high-performance materials.

-

Corrosion Resistance: One of the primary advantages of thermal spray buffalo coatings is their ability to resist corrosion. This is particularly important in industries such as aerospace, automotive, and marine, where components are exposed to harsh environmental conditions.

-

High Temperature Resistance: Thermal spray buffalo coatings can withstand extreme temperatures without degrading. This makes them suitable for applications involving high-temperature environments, such as gas turbines and furnace components.

-

Improved Performance: The application of buffalo-derived coatings can enhance the overall performance of machinery and equipment. By providing a protective layer, these coatings reduce friction and improve efficiency, leading to better operational outcomes.

-

Versatility: Thermal spray buffalo coatings can be applied to a wide range of substrates, including metals, ceramics, and composites. This versatility makes them applicable in various industries, from manufacturing to energy production.

Applications of Thermal Spray Buffalo Coatings

Thermal spray buffalo coatings are used across a range of industries due to their remarkable properties. Some common applications include:

-

Aerospace: In the aerospace industry, thermal spray buffalo coatings are used to protect turbine blades, landing gear, and other critical components from extreme conditions.

-

Automotive: Automotive manufacturers use these coatings to enhance the performance and longevity of engine parts, pistons, and exhaust systems.

-

Marine: In the marine sector, thermal spray buffalo coatings are applied to ship hulls and propellers to combat corrosion and wear from saltwater.

-

Energy: Thermal spray coatings are crucial in energy production facilities, where they protect components in gas turbines and other high-temperature environments.

The Future of Thermal Spray Buffalo Manufacture

The field of thermal spray buffalo manufacture continues to evolve with advancements in technology and materials science. Ongoing research and development are focused on improving the efficiency and effectiveness of these coatings, leading to even greater benefits for various industries.

Conclusion

In summary, thermal spray buffalo manufacture represents a significant advancement in protective coating technology. By offering enhanced durability, corrosion resistance, and high-temperature performance, these coatings play a crucial role in extending the lifespan and improving the functionality of components across diverse industries. As technology continues to advance, the role of thermal spray buffalo coatings will undoubtedly become even more prominent, driving innovation and efficiency in manufacturing and beyond.