Plasma spray

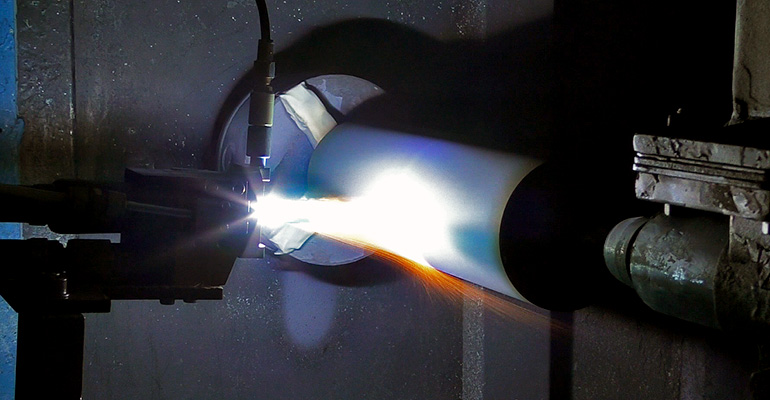

Plasma spray is a thermal spray process used to apply coatings onto surfaces. It involves the melting of coating materials in a plasma jet and propelling them onto a substrate. Here's how plasma spray works:

-

Plasma Generation: The process begins with the generation of a plasma jet. Plasma is an ionized gas consisting of positively charged ions and free electrons. In plasma spray, plasma is typically generated by passing a gas, such as argon, through an electric arc. The gas becomes ionized, forming a high-temperature plasma flame.

-

Powder Injection: The coating material, typically in the form of a powder, is injected into the plasma flame using a carrier gas, such as argon or nitrogen. The powder is introduced into the plasma flame in a controlled manner, where it rapidly melts and partially vaporizes due to the high temperature of the plasma.

-

Coating Deposition: The molten and semi-molten particles of coating material are propelled towards the substrate by the force of the plasma jet. Upon impact with the substrate, the particles flatten and solidify, forming a coating layer. This process is repeated until the desired coating thickness is achieved.

-

Substrate Preparation: Prior to coating deposition, the substrate surface is typically prepared to ensure adhesion and improve coating performance. This may involve cleaning, roughening, or applying a bond coat layer to promote adhesion between the substrate and the coating.

-

Control and Monitoring: Throughout the plasma spray process, parameters such as plasma gas flow rate, powder feed rate, torch traverse speed, and substrate temperature are carefully controlled and monitored to achieve the desired coating quality and properties.