Thermal spray cold spray

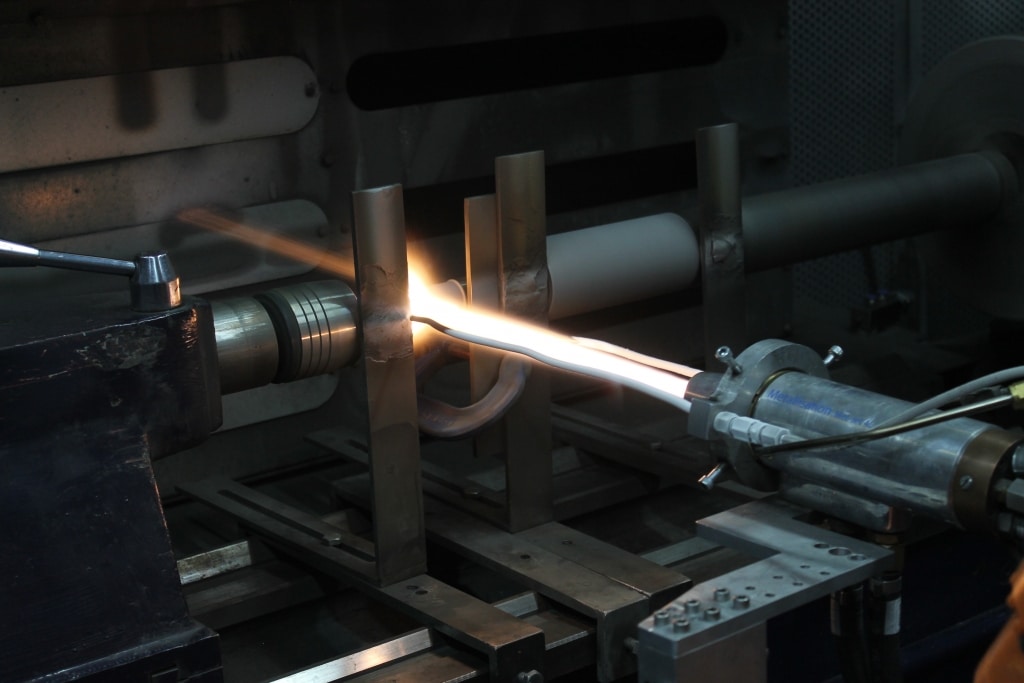

Thermal spray, including the cold spray process, is a technology used to apply various coatings onto surfaces. Cold spray is a subset of thermal spray methods, distinguished by the fact that it operates at relatively low temperatures compared to other thermal spray techniques. Here's a brief overview:

Thermal Spray:

- Definition: Thermal spraying involves melting or heating a coating material (in powder, wire, or rod form) and propelling it onto a surface using a high-velocity stream of gas or air.

- Applications: It is used for various purposes including corrosion protection, wear resistance, thermal barrier coatings, and restoration of damaged components.

- Processes: Thermal spray encompasses several methods such as flame spraying, arc spraying, plasma spraying, and cold spraying.

Cold Spray:

- Definition: Cold spray is a thermal spray process where powdered material is accelerated to supersonic speeds (typically around 300-1200 m/s) using compressed gas, impacting a substrate and forming a coating without significant heating of the powder or substrate.

- Advantages: Compared to traditional thermal spray methods, cold spray offers advantages such as lower substrate temperatures, reduced oxidation of materials, minimal distortion or thermal stress on the substrate, and the ability to deposit a wide range of materials, including metals, ceramics, and polymers.

- Applications: Cold spray has applications in aerospace, automotive, electronics, and other industries where precise, low-temperature coatings are required for sensitive materials or components.

- Materials: Various materials can be deposited using cold spray, including aluminum, copper, stainless steel, titanium, nickel-based alloys, ceramics, and more.