Metal and Metal Alloy Coatings

• Metal alloys can be used as bond coatings for other thermal spray coatings

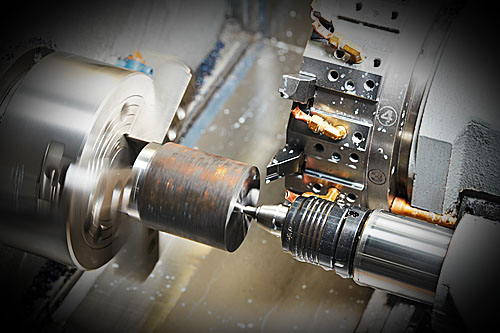

• Nickel and Ni alloys such as NiAl are commonly used for dimensional buildup of parts for ease of

machining

• Stainless steel, NiCr, etc. can be used to restore dimensions or to put an improved surface for wear and

corrosion.

• Stellite, Triballoy, and other tribological materials can be used for improved performance over an easily

fabricated base material.

• Molybdenum (Mo) and other refractory metals can be used for high temperature wear resistance, for sliding

wear, and applications requiring lubricity. Widely used on automotive parts.

• Cobalt (Co), Tantalum (Ta), Chromium (Cr), Tungsten (W) and similar types of materials offer specialized

properties.

• Copper (Cu) and Aluminum (Al) based materials are used for corrosion resistance, electrical conductivity,

thermal conductivity, and other applications

• MCrAlY’s, such as CoCAlY, NiCrAlY, CoNiCrAlY and NiCoCrAlY, are used for hot oxidation protection and

corrosion protection in gas turbine applications and in high temperature wear and corrosion up to 1000°C.

They are also excellent bond coat materials.

Common coatings:

• MCrAlY’s (NiCrAlY, CoCrAlY, NiCoCrAlY, CoNiCrAlY)

• Nickel Aluminum alloys (NiAl) ,Nickel Chrome

• Molybdenum (Mo) and Mo alloys

• Titanium (Ti)

• Stellite : # 1,12, 6, 20, 21

• Triballoy

• Ferrous alloys : SS 316, 304, 413, 420, 174Ph

• Non Ferrous alloys : Cu, Al, Ph Bronze, Al Bronze, Babbitt